-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

As a power system specialist, I measure breaker reliability by the way it behaves under stress, not on paper. In factories, data centers, and healthcare facilities, I have seen ABB moldedŌĆæcase and power breakers protect people and equipment countless timesŌĆöand I have also seen how small issues in installation, settings, or maintenance can masquerade as ŌĆ£bad breakers.ŌĆØ This guide distills proven methods to separate symptoms from root causes and to diagnose ABB circuit breakers efficiently and safely. The techniques come from field practice and align with reputable guidance from Global Electronic Services, NASA Lessons Learned, NETA/TestGuy, the U.S. Bureau of Reclamation, and other professional sources.

A breaker trip is not a nuisance; it is a safety signal. According to industry summaries referenced by electrical service firms citing NFPA, residential electrical problems contribute to tens of thousands of fires and billions in property damage annually, and the stakes are even higher when industrial loads, critical UPSŌĆæbacked systems, and power electronics are involved. ABB breakersŌĆölike peers across the industryŌĆöinterrupt dangerous currents during overloads, short circuits, ground faults, and arcŌĆæfault conditions. Reliable interruption preserves equipment, keeps uptime high, and, most importantly, protects people. When trips recur, when a breaker will not reset, or when overheating and discoloration appear, a structured diagnosis prevents guesswork, avoids unsafe ŌĆ£keep resettingŌĆØ behavior, and shortens downtime.

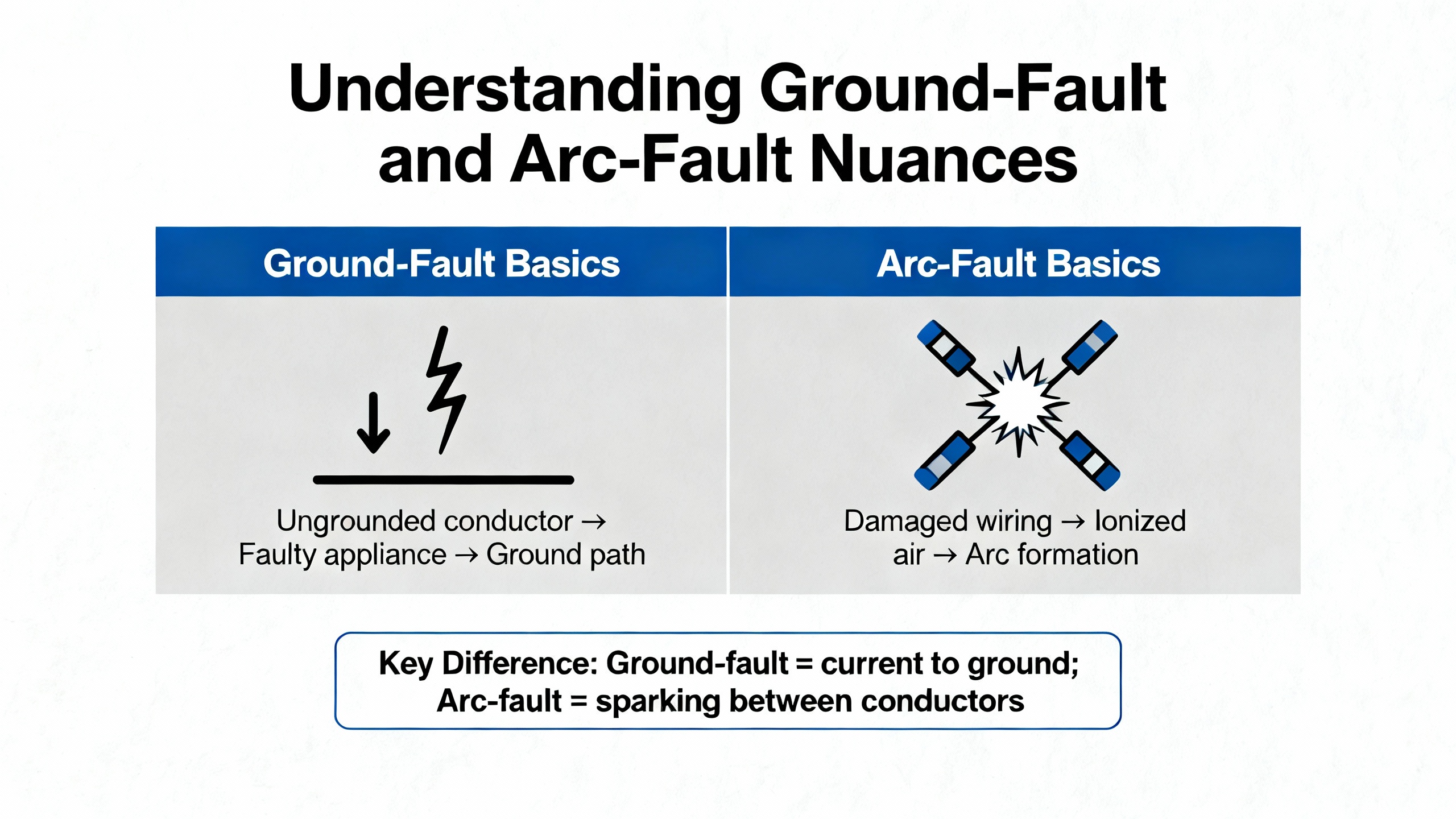

A breaker trips because its protective element sees a condition that exceeds the safe envelope. Overloads develop when too many devices draw current on one branch or feeder; in practice this often appears after adding another highŌĆæwattage appliance to a circuit already near capacity. Short circuits happen when a live conductor contacts neutral or another live phase, producing a nearŌĆæinstant spike that trips immediately. Ground faults occur when current escapes to ground through a chassis, conduit, water, or a person; modern systems apply groundŌĆæfault protection to reduce shock risk and fire potential. Arc faults differ again: loose or damaged conductors create sustained arcing that runs hot, and dedicated arcŌĆæfault devices detect the signature. These fundamentals, consistently emphasized by electrical contractors and maintenance references, anchor every diagnostic step.

Trust the trip. Treat every unexpected trip as a signal to stand down, not to force a reset. Before troubleshooting, deŌĆæenergize and verify with the right tester; use insulated tools; wear appropriate PPE; and barricade the work area when there is any chance of arcing. NASAŌĆÖs Lessons Learned guidance underscores supervisor hazard briefings, qualified personnel, and PPE such as nonmetallic hardhats with chin straps, safety goggles, rubber gloves and sleeves, insulating blankets or mats, and signage. Breaker exteriors should not exceed approximately 140┬░F; persistent temperature rise near that levelŌĆöespecially under modest loadingŌĆöwarrants further investigation, as noted in facility troubleshooting briefs. Never tighten terminals or perform maintenance on energized breakers. If you are not licensed and trained for panel work, stop here and call a professional.

When a facility calls about a breaker that ŌĆ£just keeps tripping,ŌĆØ I start outside the panel. First, switch off or unplug the loads fed by the affected breaker. Reset the handle by moving it fully to OFF with a firm action, then back to ON. Reintroduce loads one by one and observe. An immediate retrip on reset or when a particular device is plugged in points to a short or ground fault. A trip after some time under load suggests an overload or marginal connections that heat up under current. In wet or outdoor areas, investigate GFCI devices; incorrect line/load wiring on a GFCI, a common field mixŌĆæup discussed in professional forums, will create puzzling symptoms until corrected. In spaces renovated recently or with new electronics, consider arcŌĆæfault protection and the possibility that loose terminations or damaged cords are driving arc signatures. If multiple circuits show symptoms after a storm or utility disturbance, include surge events in your hypothesis and examine surge protection.

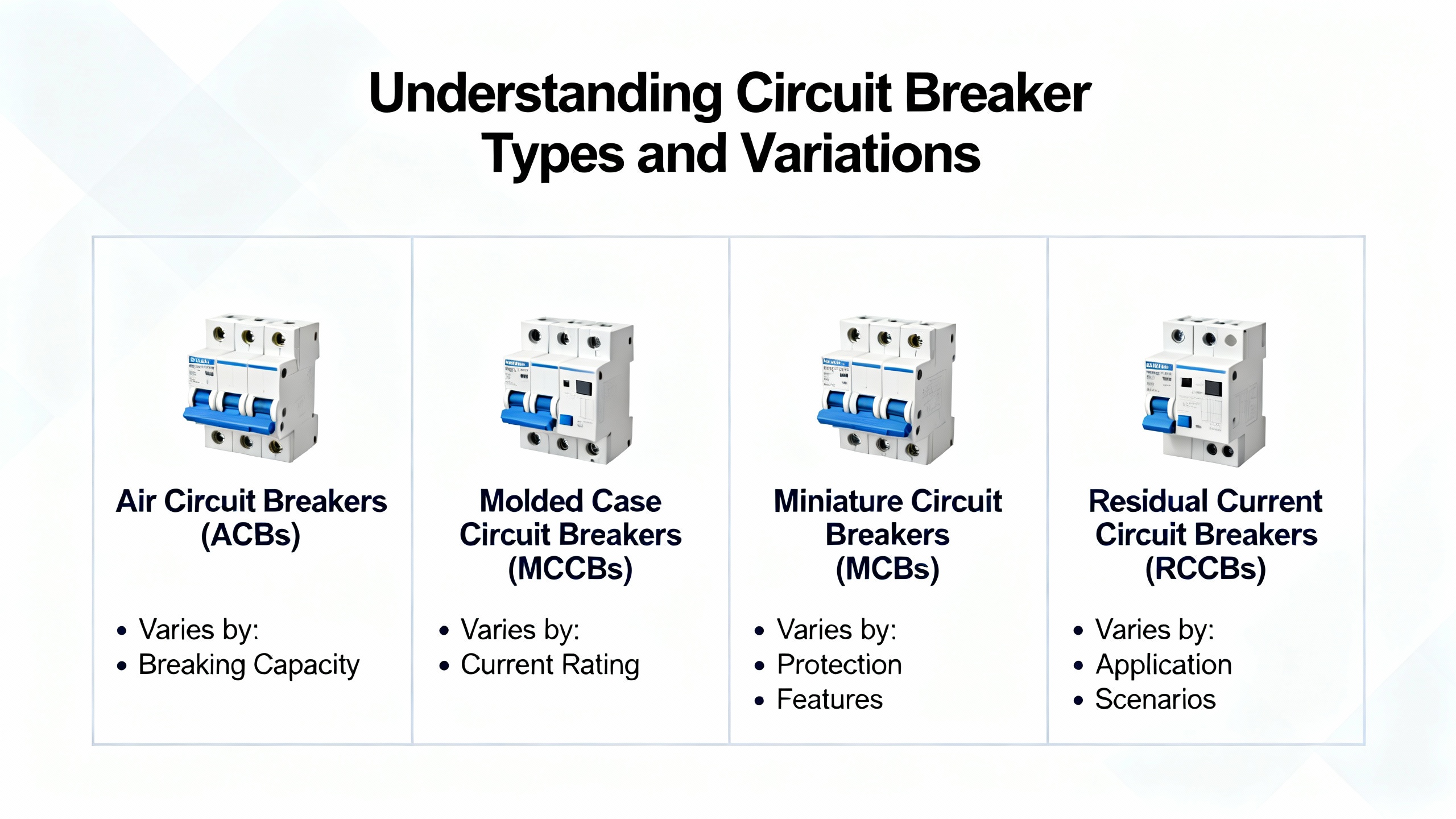

Although ABBŌĆÖs product family is broad, the diagnostic approach holds across moldedŌĆæcase circuit breakers (MCCB), insulatedŌĆæcase or lowŌĆævoltage power circuit breakers (LVPCB), and mediumŌĆævoltage families. Trip technologyŌĆöthermalŌĆæmagnetic elements, electronic trip units, vacuum bottles, and othersŌĆöchanges the tools and intervals but not the logic. Manufacturer instructions govern settings and test limits, and OEMŌĆæcertified technicians should handle any operation that exposes internal trip mechanisms or involves primary injection on large frame sizes. Always align testing with ABB manuals and site coordination studies.

A disciplined visual and mechanical inspection solves more than half of the ŌĆ£bad breakerŌĆØ complaints I see. Start with the environment. Panels exposed to dust, humidity, corrosive air, vibration, or rodents age faster and deserve shorter maintenance intervals. Inside the cubicle or panel, look for water stains, rust, insects, or other contamination that can bridge insulation. On the breaker, check housings, arc chutes, and the full contact stack for heat discoloration; inspect protective accessories and auxiliary devices; and verify that mechanical linkages move freely when you open and close the handle or push the test provision. Torque checks on lugs and bus connections should follow calibrated values; maintenance specialists point out that ŌĆ£blind reŌĆætorquingŌĆØ risks conductor damage and does not substitute for proper cleaning and retightening.

Experienced technicians validate what they see with measurements. The core tests below appear consistently in industrial breaker maintenance programs and specialist publications.

| Test or Measurement | Purpose | Typical thresholds or interpretations | Source context |

|---|---|---|---|

| Millivolt drop (highŌĆæcurrent DC) | Detect eroded or contaminated contacts and loose pivots | Drive approximately 50ŌĆō100 A DC through each pole and compare voltage drops phaseŌĆætoŌĆæphase; outliers indicate abnormal resistance | Global Electronic Services maintenance guidance |

| Overload tripping (functional) | Verify trip performance of thermal/magnetic or electronic elements | Apply approximately 300% of the breakerŌĆÖs continuous rating and confirm automatic opening; compare to timeŌĆæcurrent characteristics | Global Electronic Services |

| Insulation resistance (IR), DAR, PI | Assess insulation health and dryness | Record at 30 seconds and 1 minute to calculate DAR; above 1.6 is excellent; 1.0ŌĆō1.25 is questionable. With 10ŌĆæminute data, PI above 4 is excellent and below 1 is dangerous. Temperature and humidity strongly affect readings | Global Electronic Services |

| Insulation megger minimum | Establish a pass/fail floor | A minimum acceptable value of roughly 1 megohm measured after at least 1 minute is cited for basic acceptance; some programs require much higher values | NASA Lessons Learned; NETA/TestGuy commentary |

| Contact resistance (ductor) | Quantify conductor and contact path resistance | Investigate when one phase exceeds the lowest by more than fifty percent or is greater than oneŌĆæandŌĆæaŌĆæhalf times the lowest. Large deltas demand cleaning or replacement | NETA/TestGuy; Global Electronic Services |

| OverŌĆæpotential (hiŌĆæpot) | Reveal weak insulation and contamination paths | HighŌĆæpotential DC stresses insulation. Use only the specified test set on vacuum devices, as incorrect testing can damage bottles and produce XŌĆærays during internal arcing | Global Electronic Services |

| Timing and motion (LV/MV/HV) | Confirm opening speed, travel, and synchronization | LowŌĆævoltage units use primary injection (preferred) or secondary injection; medium/highŌĆævoltage units use a travel analyzer with a transducer to record speed, travel, binding, and bounce | Global Electronic Services |

| MV oil dielectric | Verify interrupter medium condition | Oil with dielectric strength below about 22 kV requires filtering or replacement | Global Electronic Services |

| Surface temperature | Flag thermal stress under load | Exterior surfaces should remain well below approximately 140┬░F in normal service; higher readings require load and connection checks | Tameson troubleshooting brief |

Two trends matter more than any single reading: compare all three phases, and record values over time. Programs that log IR, contact resistance, and millivolt drop data catch early degradation and make ŌĆ£replaceŌĆØ decisions objective.

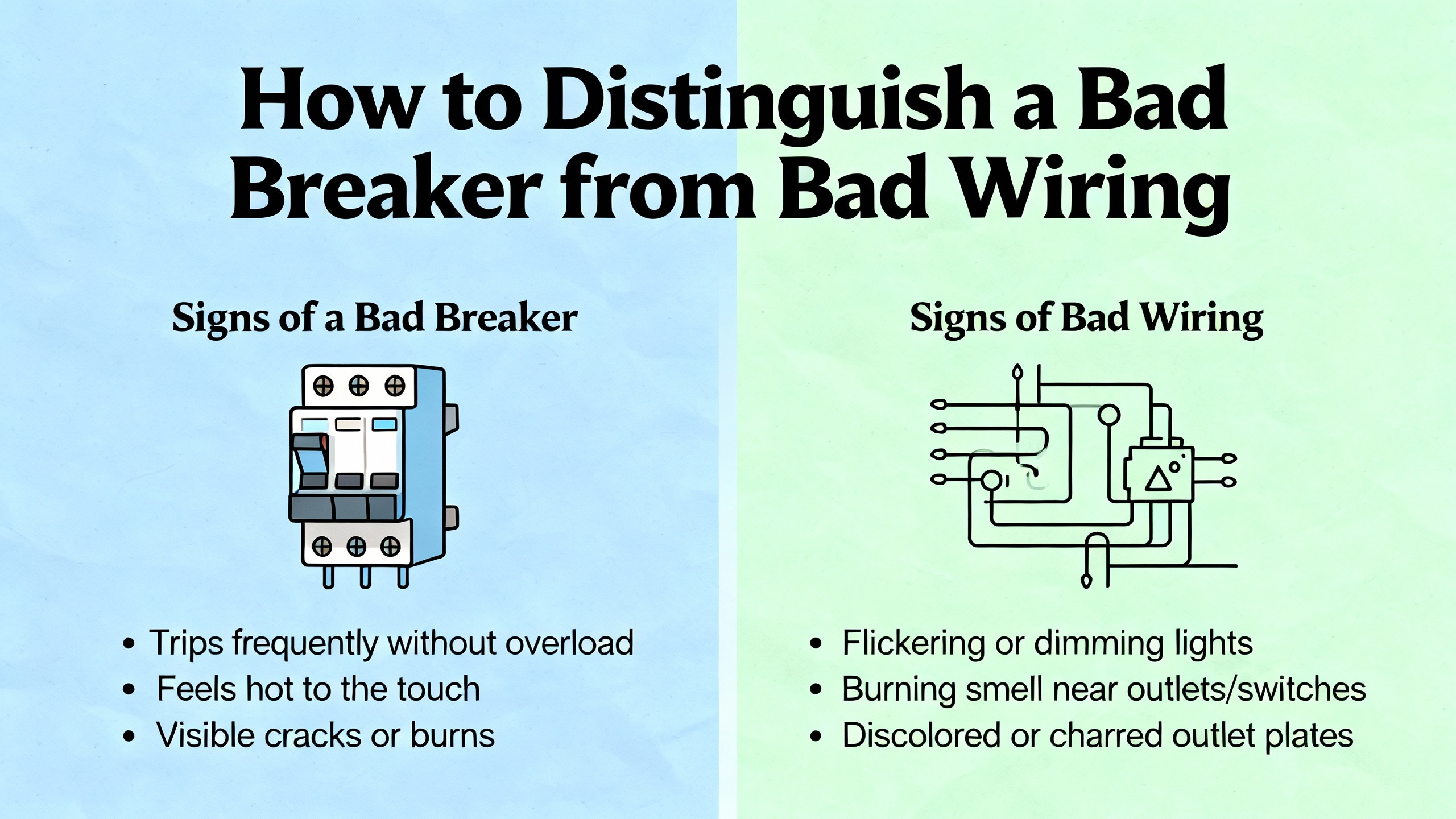

Panel symptoms sometimes track the breaker; sometimes they stay with the circuit. One controlled method is to swap the suspect ABB breaker with a knownŌĆægood unit of the exact same type and rating in the same panel position class, performed by a qualified person with documentation and photos. If the symptom follows the breaker to its new location, replace the breaker. If the symptom remains on the original circuit, the circuit likely has a wiring fault; keep in mind that stressed wiring can also damage the breaker, so replacing both the wiring section and the breaker may be prudent once the wiring fault is corrected. While in the panel, verify torque on all terminations. This practical technique is widely described by field technicians and aligns with the broader principle of ŌĆ£change one variable at a time.ŌĆØ

A veteran troubleshooting trick from professional electricians is to insert a highŌĆæwattage incandescent lamp in series at the breaker output as a temporary current limiter during faultŌĆæfinding. The lamp absorbs energy and glows bright when a short exists, keeping the breaker from instant retrip and giving you a visual cue as you isolate branch segments. This is a shortŌĆæterm diagnostic setup only, handled by qualified personnel using an appropriate rubber socket or receptacle and standard safety practices. Never leave a series lamp in service; once you find and clear the fault, remove it and restore normal wiring.

GroundŌĆæfault protection trips on current that leaks to ground, a lifesaving function especially in kitchens, baths, outdoor circuits, and industrial washdown areas. Miswired GFCI devicesŌĆöparticularly reversed line and loadŌĆöcause persistent, confusing trips or refusal to reset, a pattern repeatedly reported by practitioners. Verify the wiring and use the builtŌĆæin test and reset functions. ArcŌĆæfault protection targets the fire risk posed by damaged cords, loose terminations, or degraded insulation; when arcŌĆæfault breakers or outlets nuisanceŌĆætrip, examine cord quality, device compatibility, and conductor integrity before assuming the breaker is at fault. For both technologies, confirm that the ABB protection selected matches code needs, the load characteristics, and the environmental exposure.

Even the best breaker ages faster in a harsh environment. Maintenance guidance is consistent across credible sources. MoldedŌĆæcase units are generally lowŌĆæmaintenance but should be exercised at least annually; routine trip testing every three to five years is common for standard duty cycles. LowŌĆævoltage power breakers warrant inspection and maintenance roughly every one to three years, with shorter intervals in dusty, corrosive, hot, or humid atmospheres, on aging gear, where switching is frequent, or where currents run near rating. MediumŌĆævoltage breakers should see maintenance about annually or after approximately 2,000 operations, whichever comes first. HighŌĆævoltage breakers should be inspected on a sixŌĆæ to twelveŌĆæmonth cadence. Many insurers and service providers recommend a minimum annual panel inspection for commercial occupancies and more frequent checks for critical service. These intervals, drawn from Global Electronic Services, U.S. Bureau of Reclamation practices, and industry maintenance programs, should be tailored to your duty cycle and environment.

Good diagnostics are as much about paperwork as they are about probes. Record every inspection, test method, test set, ambient conditions, and result. Trend data will catch subtle drifts long before failures. Certifications and thirdŌĆæparty reportsŌĆösuch as conformance to ANSI and NEMA standards or typeŌĆætest documentation like KEMAŌĆöstrengthen quality assurance in large programs. NASAŌĆÖs Lessons Learned database documents a counterfeit breaker case where refurbished units were sold as new, with mislabeled ratings and failure to trip, in some cases violently. The mitigation was simple and sobering: vet suppliers rigorously and test breakers prior to or at installation using defined criteria. The lesson applies broadlyŌĆöstick to authorized ABB channels and insist on traceable test reports.

A breaker that shows heat damage, cracked housings, burnt odor, or will not hold the ON position under normal load is not a candidate for longŌĆæterm repair in a critical facility. Replacement with the correct ABB catalog number and accessoriesŌĆöthrough an authorized channelŌĆöremains the safest course. When the breaker is mechanically sound but shows elevated contact resistance or slow timing, a qualified service shop can clean, reŌĆælube, calibrate, and certify the unit. Restoration services disassemble, replate, recoat, and retest to extend life. For older panels struggling with modern loads, retrofits to electronic trip units with adjustable pickup and delay can improve selective coordination and reduce nuisance trips, provided settings are engineered. When upstream or downstream devices require changes to trip values, always revisit the coordination study rather than tweaking dials in isolation.

When specifying a replacement or adding capacity, start with the basics: continuous current rating, voltage class, and interrupting rating appropriate to the available fault current. Add the trip unit features you needŌĆögroundŌĆæfault pickup and delay, zone interlocking, and communicationŌĆöwithout overcomplicating operation for maintenance teams. Verify environmental suitability, enclosure ratings, and accessory compatibility. Do not mix breaker types or frame classes where the switchboard or panelboard lists restrict it. Align with ANSI/NEMA standards and insist on complete documentation, including production test results or a service test report if reconditioned. Purchase through authorized channels and avoid grayŌĆæmarket bargains; counterfeit cases are rare but real. In spare strategy, carry at least one readyŌĆætoŌĆæinstall breaker for each critical frame size, stored in a clean, dry, temperatureŌĆæcontrolled location and cycled per OEM guidance to keep lubrication distributed.

The quickest way I communicate next steps is to connect symptoms to hypotheses and actions. If a breaker trips instantly on reset, think short or ground fault, unplug everything on that branch, and test outlets and cords. If it trips after running for a while, think overload or marginal terminations; measure load current and check torque on lugs. If GFCIs or arcŌĆæfault devices are involved, verify wiring and use their test/reset features. If panel connections look clean and the issue persists on one circuit, swap in a matched breaker of the same type and rating to see whether the symptom follows the breaker or stays with the wiring, and document every step. If the panel is warm, if the breaker smells burnt, or if you see discoloration, stop and escalate to a licensed electrician. Resist the urge to defeat protection by overŌĆæfusing or taping a handleŌĆöpower quality and uptime never justify safety compromises.

While many ABB lowŌĆævoltage diagnostics carry to mediumŌĆæ and highŌĆævoltage gear, the test sets and hazards scale up. For mediumŌĆævoltage, plan annual maintenance or use operation counts as a trigger. Oil interrupters demand dielectric strength checks, filtering, or oil replacement when values fall. Vacuum devices require the correct highŌĆæpotential test methodology to avoid bottle damage and XŌĆæray emission risk during internal arcing events. For drawŌĆæout frames, timing and travel analyzers reveal subtle mechanical binding and contact bounce. Always use trained crews with the right barricades and test equipment calibrated for the voltage class.

Clean, dry, and cool go a very long way. Keep panels accessible and free of dust accumulation; correct water ingress immediately; and mitigate corrosive atmospheres. Exercise breakers on the OEM cadence to distribute lubrication. Perform infrared scans during peak production to catch hot lugs long before smells or discoloration appear. Calibrate electronic trip units when you change system topology or after significant fault events. Label circuits clearly so operators can reset correctlyŌĆöhandle fully OFF, then ONŌĆöwithout pounding at the panel. In aging buildings or expanded campuses, plan capacity upgrades and the addition of dedicated circuits for heavy loads instead of stretching existing ones past their comfort zone.

| Item | Practical guidance for the field | Source context |

|---|---|---|

| MCCB functional checks | Exercise annually; perform routine trip testing every three to five years depending on duty | Global Electronic Services |

| LV power breaker maintenance | Inspect and maintain approximately every one to three years; shorten interval in harsh conditions or heavy use | Global Electronic Services |

| MV/HV intervals | Maintain mediumŌĆævoltage annually or after approximately 2,000 operations; inspect highŌĆævoltage on a sixŌĆæ to twelveŌĆæmonth cycle | U.S. Bureau of Reclamation; ServiceChannel |

| IR/DAR/PI trending | Measure at 30 seconds, 1 minute, and 10 minutes when applicable; DAR above 1.6 and PI above 4 indicate healthy insulation, with strong dependence on environment | Global Electronic Services |

| Contact resistance tolerance | Investigate when one phase deviates more than fifty percent or exceeds oneŌĆæandŌĆæaŌĆæhalf times the lowest value | NETA/TestGuy; Global Electronic Services |

| Safety baseline | DeŌĆæenergize, verify absence of voltage, use PPE, insulated tools, and barricades | NASA Lessons Learned |

What is the minimum acceptable insulation resistance on a lowŌĆævoltage breaker or feeder, and how should I measure it? A common floor used in maintenance programs is roughly 1 megohm measured after at least one minute of stabilization, with many facilities adopting higher thresholds based on NETA guidance. Record values at 30 seconds and one minute to compute the dielectric absorption ratio, and include a 10ŌĆæminute reading for polarization index when windings are present. Temperature and humidity change readings significantly; trend results over time rather than relying on a single number.

How can I tell if the breaker is bad or the circuit wiring is at fault? A controlled technique is to swap the suspect breaker with a knownŌĆægood unit of identical type and rating in the same panel class, performed by a qualified person with full documentation. If the symptom follows the breaker to the new slot, replace the breaker. If the symptom stays on the original circuit, troubleshoot the wiring, recognizing that damaged wiring can also weaken the breaker.

Is there a quick way to keep a breaker from retripping instantly while I locate a short? Some electricians temporarily place a highŌĆæwattage incandescent lamp in series at the breaker output as a current limiter. The lamp brightness helps locate the fault while limiting current. This is an interim diagnostic method only, conducted with proper insulation, and it must be removed once the fault is found.

My breaker is warm to the touch. How hot is too hot? Exterior temperatures near approximately 140┬░F deserve attention. Use an infrared thermometer or camera to verify temperature, measure load current, and inspect terminations. If you see scorch marks, smell burning, or hear buzzing, deŌĆæenergize and call a licensed electrician.

How often should ABB breakers be maintained in a manufacturing plant? For moldedŌĆæcase units, exercise annually and perform functional trip tests every three to five years if duty is modest. For lowŌĆævoltage power breakers, plan inspection and maintenance about every one to three years, sooner in harsh environments or high duty. For mediumŌĆævoltage, maintain on roughly an annual basis or after about 2,000 operations, and inspect highŌĆævoltage devices every six to twelve months. Align intervals with ABB manuals and your facilityŌĆÖs duty cycle.

What tests should I prioritize if I only have time for a few? Start with a clean visual and mechanical inspection, then perform millivolt drop to find bad connections and an insulation resistance test to assess insulation condition. If results suggest deeper issues, add contact resistance, functional trip testing, and timing or travel analysis depending on breaker class.

ABB circuit breakers protect people and assets by turning dangerous faults into controlled outages. Most ŌĆ£mystery tripsŌĆØ become predictable once you anchor diagnosis in first principles, check the environment, use a few highŌĆævalue tests, and document results. Prioritize safety and training, match your methods to ABBŌĆÖs manuals and industry standards, and schedule maintenance based on real duty and conditions, not wishful thinking. When in doubt, bring in a licensed professional. The goal is not merely to reset a breaker, but to restore selective, reliable protection across the whole electrical system.

Global Electronic Services, circuit breaker maintenance practices and test methods. NASA Lessons Learned, breaker maintenance, testing, PPE, and counterfeit risk notes. NETA/TestGuy, moldedŌĆæcase maintenance, torque, IR thresholds, and contact resistance tolerances. U.S. Bureau of Reclamation, maintenance intervals for MV and inspection intervals for HV. Highland Electric and similar facility maintenance sources, safety context and household circuit ratings. BMElectric and related service firms, practical definitions and signs of trouble. Mike Holt Forum, seriesŌĆælamp current limiter troubleshooting tip. Tameson, breaker temperature and multimeter tips. ServiceChannel, maintenance checklists and conditionŌĆæbased maintenance ideas. Titus Electrical Services and GNY, inspection cadence, upgrade advice, and safety reminders. Parker & Sons and comparable contractor guidance, triage workflows and prevention.

Leave Your Comment