1. Introduction to DCS Systems

A Distributed Control System (DCS) is a multi-level computer control system composed of process control and process supervision layers connected through a communication network.

It integrates technologies such as Computer, Communication, Display (CRT), and Control, providing features like distributed control, centralized operation, hierarchical management, flexible configuration, and convenient maintenance.

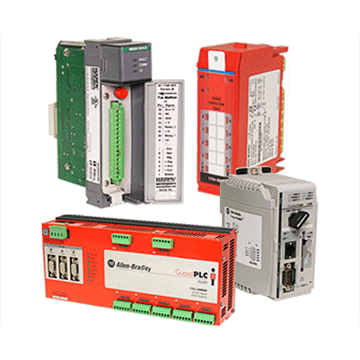

2. I/O in DCS Control Systems

A DCS must process the input and output signals of the control system, known as I/O (Input/Output).

DCS I/O modules are typically modularized, with each module containing one or more channels for connecting sensors and actuators (such as control valves).

Control Unit Structure

A process control unit (PCU) usually consists of several racks, each capable of holding multiple modules.

The rack that contains the CPU is called the CPU rack.

A single process station has only one CPU rack, while other racks serve as I/O racks connected through the field bus.

Common I/O Signal Types

AI (Analog Input) – Analog input signal

AO (Analog Output) – Analog output signal

DI (Digital Input) – Digital input signal

DO (Digital Output) – Digital output signal

3. System Selection, Design, and Commissioning

(1) System Architecture and Controller Configuration

When designing the system, control load and redundancy must be considered.

Communication load rates should remain within a reasonable range to prevent system lag or overload.

(2) Control Logic Distribution

Control logic should be distributed evenly among controllers instead of concentrating on a single one.

Critical control loops should employ redundant configurations to enhance reliability.

(3) Power Design

The DCS power supply must ensure stability and reliability.

It is recommended to adopt a dual-redundant power configuration so that if one power source fails, the system continues operating normally.

(4) System Interface Design

System interface reliability is essential for stable operation. Pay special attention to:

The selection of interface types;

Redundant interface configurations;

Communication isolation and anti-interference measures.

4. DCS Grounding System

System grounding must strictly follow the manufacturer’s specifications to prevent system faults caused by improper grounding.

I/O channels should have shielding and isolation;

Cable routing should be neat and separated between signal cables and control/computer communication cables;

Emphasize proper handling of signal grounding and cable shielding.

5. System Configuration and Protection

(1) Cabinet Configuration

Based on operational characteristics and fault-handling requirements, configure operator stations and backup operator devices accordingly.

Emergency stop buttons should use independent hardware circuits separate from the DCS.

(2) Protection System

The protection system should adopt multi-layer and logical redundancy, ensuring that signal loops possess fault isolation and logical judgment capability under abnormal conditions.

6. Equipment Commissioning

Commissioning should be conducted systematically:

Perform comprehensive logic, loop, and operating condition tests;

Verify parameter correctness and configuration reasonableness;

Ensure stable and reliable system operation.

Conclusion

The DCS is the core technology of modern industrial automation.

Its distributed architecture and modular design provide high reliability, scalability, and flexibility.

Proper system design, rational hardware configuration, and standardized commissioning are critical to ensuring safe and efficient operation in process industries.