What is a DCS System?

A Distributed Control System (DCS) is a highly sophisticated system designed to control complex industrial processes that span multiple stages. Unlike traditional centralized systems, where a single controller is responsible for all tasks, a DCS spreads control across multiple smaller, decentralized units. This approach ensures that even if one component fails, the overall system continues to function. By integrating cutting-edge technologies, such as computing, communications, and control mechanisms, DCS offers an efficient solution for handling intricate industrial operations.

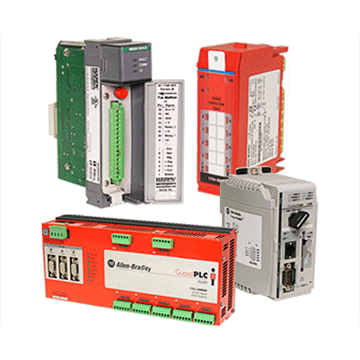

Essential Components of a DCS

A typical DCS consists of several core components, including field control units (I/O stations), data communication networks, operator interfaces (HMIs), and power supply units. The system's modular structure provides flexibility, allowing easy expansion and integration. The field control units manage the communication between devices and the central system, while the communication network ensures smooth data flow across the platform. The human-machine interface (HMI) allows users to interact with the system and monitor operations in real-time. Additionally, the power supply components maintain continuous functionality, ensuring reliability even in harsh industrial environments.

Advantages of Implementing DCS

DCS systems come with numerous benefits when compared to conventional control systems. One of the most notable advantages is their capability to manage complex tasks, including optimal and advanced control functions. These systems are capable of integrating vast amounts of data from various sources, providing real-time insights to both operators and engineers. Furthermore, the open architecture of DCS systems allows for significant adaptability, making them suitable for a wide range of industrial settings. Their ability to support diverse fieldbus standards makes future upgrades and system expansions easier.

Challenges Associated with DCS

Although DCS offers significant benefits, there are certain challenges to consider. A key concern is the risk of system failure due to centralization, as a fault in one part of the system can potentially disrupt operations. Additionally, the performance of a DCS can be compromised if excessive load is placed on a single unit. The process of developing and implementing a DCS can also be time-consuming and resource-heavy, potentially delaying project timelines and increasing costs.

Overcoming DCS Challenges

To overcome the challenges associated with DCS, several solutions can be implemented. First, high-reliability hardware, including backup systems, should be incorporated to ensure that the system remains operational even in the event of a failure. Furthermore, redundancy and fail-safe components can reduce the risk of system downtime. Routine system maintenance, optimization, and regular updates are also crucial for maintaining the DCS's performance and preventing issues like overloads or slowdowns.

Conclusion

To sum up, Distributed Control Systems (DCS) are integral to modern industrial operations, providing exceptional flexibility, reliability, and efficiency in managing complex processes. Despite the challenges they pose, these systems can be optimized through proper planning, high-reliability components, and ongoing maintenance. By addressing these issues proactively, DCS can continue to drive the success and growth of industries, enhancing control and supporting the future of automation.